Making Wireless IoT Project Easy, Smart, Secure.

GET A FREE SAMPLEThis plan aims to achieve real-time and accurate positioning of personnel in mine tunnels through advanced positioning technology, in order to effectively improve the level of mine production safety management, timely grasp the distribution of personnel, and quickly carry out rescue operations in case of emergencies.

1、 Advantages of UWB positioning technology

Taking into account the complex environment of mine tunnels (such as dust, humidity, electromagnetic interference, etc.) and the requirements for positioning accuracy, reliability, etc., ultra wideband (UWB) positioning technology is selected as the core positioning method of this scheme.

High precision positioning: UWB technology can achieve centimeter level or even higher precision positioning, accurately determining the specific location of personnel in mine tunnels, meeting the needs for fine management of personnel positioning.

Strong anti-interference ability: There are multiple electromagnetic interference sources in mine tunnels, such as motors, ventilation equipment, etc. UWB technology has good anti-interference characteristics and can work stably in complex electromagnetic environments to ensure accurate transmission of positioning data.

Low power consumption: The positioning device adopts a low-power design, which can extend the battery life, reduce the frequency of equipment maintenance, and is suitable for use in environments such as mine tunnels where frequent battery replacement is inconvenient.

Good penetration: Although there are obstacles such as rocks and coal seams in mine tunnels, UWB signals have a certain degree of penetration ability, which can ensure effective signal propagation and achieve continuous positioning of personnel to a certain extent.

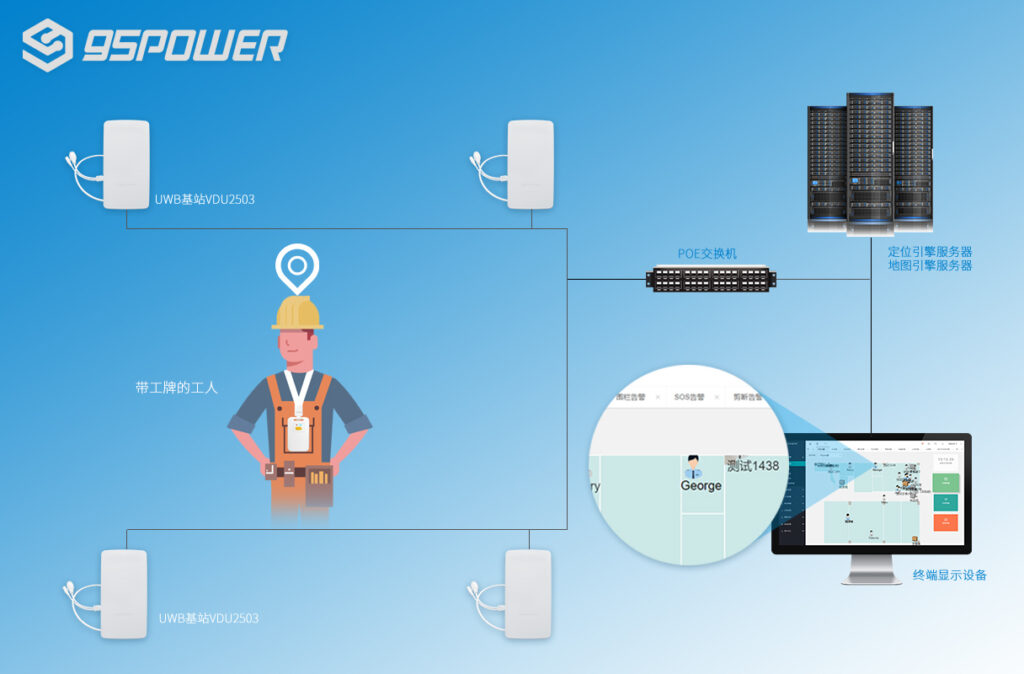

2、 System architecture

1. Positioning label

Personnel wearing: UWB positioning tags are equipped for each person entering the mine tunnel. The tags can be designed in a small and lightweight form, such as card or pendant, which is convenient to carry and does not affect the normal operation of personnel.

Functional features: The positioning tag is equipped with a built-in UWB chip, which has a unique identifier and can periodically send UWB signals containing its own ID and other related information (such as battery level, device status, etc.). The signal transmission power can be adjusted according to actual needs to balance positioning accuracy and battery life.

2. Locate the base station

Distributed deployment: Reasonably distribute and install UWB positioning base stations in the mine tunnel and near the wellhead. Based on the length, direction, branching situation of the tunnel, and the overall layout of the mine, determine the number and specific installation location of base stations to ensure effective coverage of the entire mine tunnel area.

Signal reception and processing: The positioning base station is responsible for receiving UWB signals sent by positioning tags, processing the signals, including signal strength detection, arrival time measurement, etc., and then transmitting the processed signal data to the backend server.

Network connection: The positioning base station establishes a connection with the backend server through wired (such as Ethernet) or wireless (such as Wi Fi, Zigbee, etc., depending on the existing network conditions of the mine) methods to achieve stable data transmission.

3. Backend server

Data processing and analysis: Receive signal data transmitted from positioning base stations, use positioning algorithms (such as Time Difference of Arrival (TDOA) based positioning algorithms) to process the data, calculate the precise location of each positioning tag (i.e. each person), and store the location information in real-time in a database.

Personnel management and monitoring: Comprehensive management of personnel information in mine tunnels, including basic personnel information (name, job number, department, etc.), entry time, current location, historical trajectory, etc. Through the monitoring interface, management personnel can intuitively view the distribution of personnel and keep track of personnel dynamics in real time.

Alarm and warning function: Set various alarm rules, such as personnel entering dangerous areas, personnel staying still for a long time (which may cause unexpected situations), abnormal number of personnel (exceeding the specified number), etc. When alarm conditions are triggered, the server can promptly issue alarm information and notify relevant management personnel to take corresponding measures.

Integration with other systems: It can be integrated with other related systems such as the mine's safety production management system, ventilation system, drainage system, etc., to achieve data sharing and collaborative work, providing more comprehensive support for the overall safety management of the mine.

4. Monitoring terminal

Display and operation interface: Set up monitoring terminals in places such as mine dispatch rooms and safety management offices, equipped with large screen displays and user-friendly operation interfaces, to display personnel location information, trajectory data, and various system status information. Management personnel can perform personnel queries, trajectory playback, alarm settings, and other operations through the operation interface.

Remote access: support the remote access function, allowing relevant management personnel to view the positioning of personnel in the mine tunnel in real time through the network (such as intranet or Internet, set according to security requirements) in different places (such as when the mine leader is on a business trip), so as to timely understand the safety production status of the mine.

3、 Positioning algorithm and accuracy guarantee

1. Positioning algorithm

The positioning algorithm based on Time Difference of Arrival (TDOA) is adopted, and its principle is as follows:

Measure the arrival time difference of UWB signals sent from positioning tags to different positioning base stations.

Based on the principle of constant speed of light, a hyperbolic equation system is constructed using the known location of the positioning base station and the measured arrival time difference.

By solving the hyperbolic equation system, calculate the position of the positioning label (i.e. personnel).

2. Precision assurance measures

Reasonable layout of base stations: Based on the actual shape and size of the mine tunnel, scientifically plan and locate the layout of base stations, and try to use a uniform distribution to ensure that the arrival time difference of UWB signals can be accurately measured throughout the entire tunnel area, avoiding blind spots in positioning.

Multipath effect processing: The environment of mine tunnels is complex, and UWB signals may generate multipath effects during propagation, affecting positioning accuracy. Adopting anti multipath technology, such as setting special filters in positioning base stations and positioning tags, to suppress multipath signals and improve positioning accuracy.

Time synchronization calibration: To ensure the accuracy of TDOA based positioning algorithms, strict time synchronization calibration is required for positioning base stations, which can be achieved using high-precision clock sources or through network time protocol (NTP) to ensure consistent time measurement accuracy between different base stations.

4、 System functional characteristics

1. Real time positioning and trajectory playback

Real time positioning: It can obtain and display the current location of each person in the mine tunnel in real time. Management personnel can check the distribution of personnel at any time through monitoring terminals to understand whether they are in the normal operation area.

Trajectory replay: The system automatically records the movement trajectory of each personnel in the mine tunnel. Management personnel can select specific personnel according to their needs and view their activity trajectory in the past period of time, in order to analyze their work routes, stay time, and other situations. This is of great significance for accident investigation, work efficiency evaluation, and other aspects.

2. Warning and restriction of entry into hazardous areas

Dangerous area setting: Based on the geological conditions, production process, and safety requirements of the mine tunnel, various dangerous areas are pre-set, such as goaf, water accumulation area, gas accumulation area, etc., and marked in the system.

Warning and restriction: When personnel approach or enter dangerous areas, the system can promptly issue warning signals to remind them to pay attention to safety. At the same time, a restricted access function can be set. When personnel attempt to forcefully enter a dangerous area, the system will issue an alarm and notify relevant management personnel, effectively preventing personnel from accidentally entering the dangerous area and ensuring their safety.

3. Personnel attendance management

Well entry and exit records: The system automatically records the entry and exit times of each personnel as an important basis for attendance, without the need for manual recording, improving the accuracy and efficiency of attendance management.

Attendance statistics and reports: Based on the records of entering and leaving the well, as well as the working hours of personnel in the well, the system can automatically generate attendance statistics reports to facilitate human resource management and salary accounting for enterprises.

4. Emergency rescue support

Quick location locking of personnel: In case of emergency situations such as fire or collapse, management personnel can quickly lock in the location of trapped personnel through monitoring terminals, providing accurate target information for rescue operations and saving rescue time.

Rescue path planning: Combining the map information of the mine tunnel and the current location of personnel, the system can plan the best rescue path for rescue personnel, avoid dangerous areas, improve rescue efficiency, and ensure their own safety during the rescue process.

5、 System implementation steps

1. Requirement research and analysis

Deeply understand the basic situation of the mine's scale, tunnel layout, production process, personnel quantity, as well as the specific requirements of the enterprise for personnel positioning systems, such as positioning accuracy requirements, functional requirements, budget constraints, etc.

Analyze the environmental characteristics inside the mine tunnel, including the impact of factors such as dust, humidity, and electromagnetic interference on the positioning system, and provide a basis for subsequent system design and selection.

2. System design and selection

Based on the results of the demand research, design the overall architecture of the system, including the functions and connection methods of various parts such as positioning tags, positioning base stations, backend servers, and monitoring terminals.

Select appropriate UWB positioning devices (positioning tags and positioning base stations), considering the performance parameters of the devices (such as positioning accuracy, signal transmission power, reception sensitivity, etc.), quality reliability, price, etc., to ensure that the selected devices can meet the positioning needs of mine tunnel personnel.

3. Equipment installation and debugging

According to the system design plan, positioning base stations should be installed in the mine tunnel and near the wellhead. The installation location of the base station should meet the layout planning requirements to ensure good signal coverage.

Equip each person entering the mine tunnel with a positioning tag and perform initialization settings, such as binding basic personnel information.

After completing the equipment installation, perform system debugging, including network connection debugging between the positioning base station and the backend server, testing of positioning algorithms, verification of system functions, etc., to ensure that the system can operate normally and achieve the expected positioning accuracy and functional requirements.

4. Personnel training and system acceptance

Provide systematic training for mine management and operation personnel, including the operation methods of monitoring terminals, the viewing methods of personnel positioning information, and the use of alarm functions, to ensure that they are proficient in using the system.

Organize system acceptance work, invite relevant department leaders, technical experts, etc. of the enterprise to participate, comprehensively evaluate the performance, functionality, stability, and other aspects of the system according to the acceptance standards, and officially put the system into use after passing the acceptance.

6、 System maintenance and management

1. Equipment maintenance

Regularly inspect and maintain the positioning tags and positioning base stations to check for any damage to the equipment, sufficient battery power, etc., and replace damaged equipment or batteries in a timely manner to ensure normal operation of the equipment.

Clean up dust and other debris around the positioning base station, maintain good heat dissipation of the equipment, and avoid equipment failure caused by poor heat dissipation.

2. Data maintenance

Regularly backup personnel location data and other related information in the backend server to prevent data loss or damage.

Clean and optimize data, delete expired trajectory data, etc., to improve the efficiency of database operation.

3. System upgrade

Pay attention to the development trends of UWB positioning technology, and promptly upgrade the system when there are new technological improvements or functional upgrades to improve system performance and functionality.

Adjust and optimize the system's functions in a timely manner based on the development needs of the enterprise and changes in mine production, such as adding new hazardous area settings and improving attendance management functions.

Through the above mine tunnel personnel positioning scheme, utilizing the advantages of UWB positioning technology, combined with a sound system architecture, functional characteristics, and implementation and maintenance management measures, accurate positioning and comprehensive management of personnel inside the mine tunnel can be effectively achieved, providing strong guarantees for mine safety production.

Copyrights© Shenzhen Skylab Co.,LTD All Rights Reserved.