Coal mines, tunnels, construction sites, mines and other occasions have harsh construction environments, frequent accidents, and complex management. Coal mines/tunnels/construction sites/mining construction companies face huge personnel positioning and management problems. An accurate and efficient personnel positioning solution is urgently needed.

According to the needs of customers, SKYLAB has launched a solution for the positioning of coal mine tunnels in construction sites. It can be used for personnel positioning in tunnels, pipe galleries, construction sites, mines, underground rail transit and other occasions.

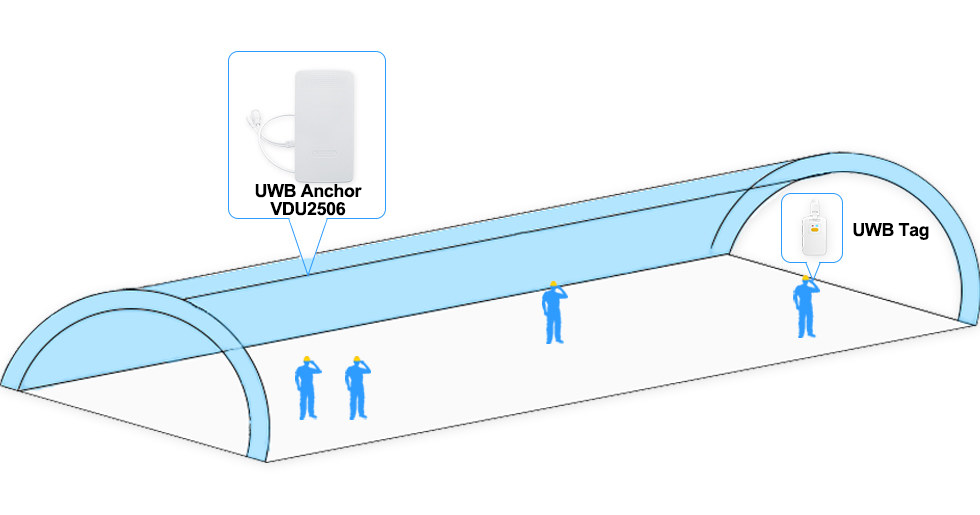

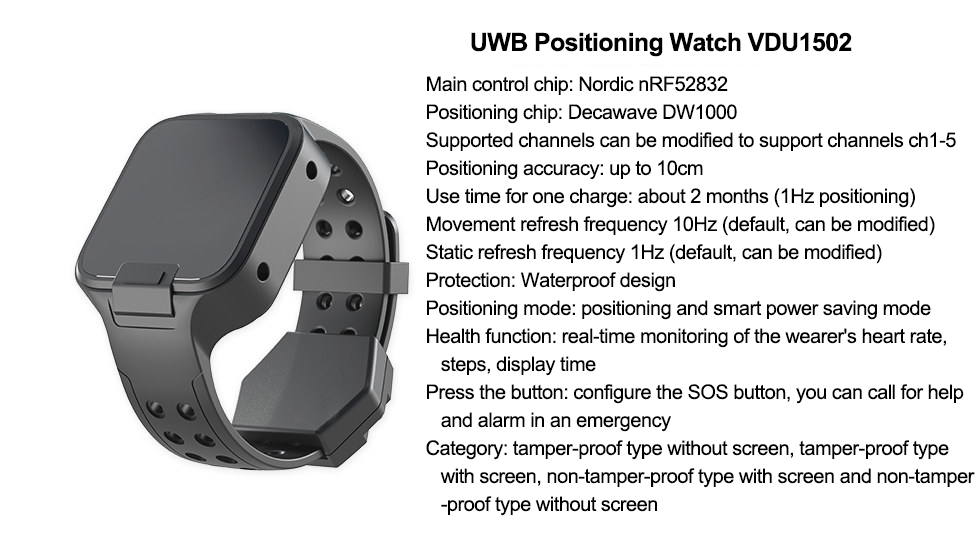

The coal mine personnel positioning solution adopts UWB positioning technology. By installing and deploying UWB positioning base stations in the area where the tunnel needs to be positioned, UWB positioning tags are provided for construction personnel or machinery and equipment. The precise location of the construction personnel can be obtained in real time, and the positioning accuracy is as high as 10 cm.

The following takes the coal mine personnel positioning solution as an example to illustrate. Through the coal mine personnel positioning solution, coal mine construction enterprises can grasp the real-time position of construction personnel in the coal mine tunnel, historical activity trajectories, and the distribution of personnel in the tunnel construction area at any time.

It can also carry out emergency rescue in time in an emergency, improve the overall production efficiency and management level of coal mine construction enterprises, and ensure the safety of construction workers.

In the UWB positioning solution for coal mines, the UWB tag worn by the construction workers transmits its own signal through the ultra-wideband pulse signal, the UWB base station receives the signal, and measures the distance between the UWB positioning tag and the base station through the signal flight time.

Then the positioning engine collects the distances between different UWB positioning base stations and tags, thereby calculating the current position of the UWB positioning tags, and displaying them on the large screen in real time.

Coal mine personnel positioning generally adopts one-dimensional positioning in UWB positioning

1. The positioning of coal mine personnel can generally be achieved by one-dimensional positioning;

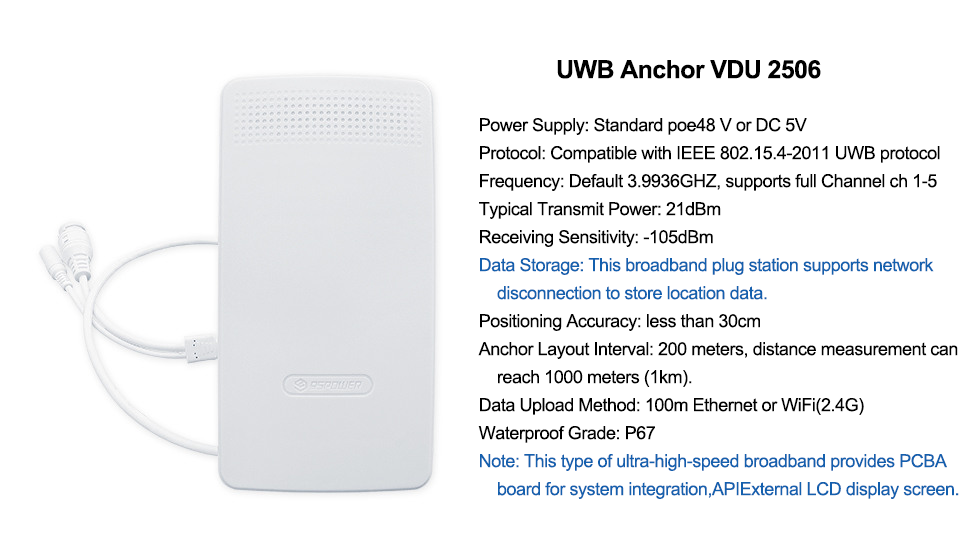

2. Install and deploy a UWB base station at intervals of 400 meters to 1000 meters in the mine tunnel of the coal mine, with a positioning accuracy of less than 30 cm;

3. Where there are bends or turns in the mine road, UWB base stations need to be appropriately added for positioning compensation.

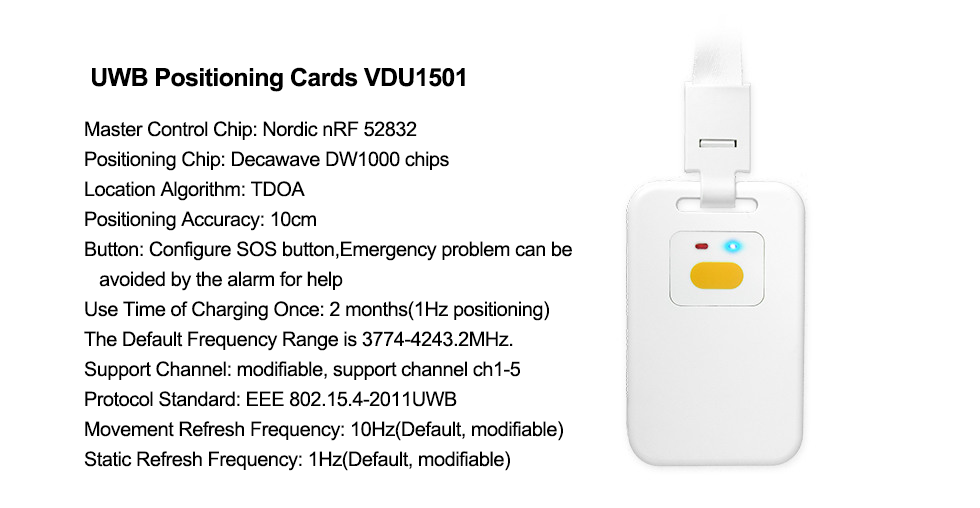

New Coal Safety standard coal mine personnel positioning solution consists of: display terminal, UWB positioning engine, UWB positioning base station, UWB positioning tag.

(1) Display terminal: The positioning label coordinates calculated by the UWB positioning engine must be displayed on the display terminal (PC, tablet, mobile phone).

(2) UWB positioning engine: The UWB positioning base station in the tunnel positioning area sends the original position data to the UWB positioning engine through the network in real time, and then the UWB positioning engine runs the positioning algorithm to calculate the coordinate position of the person wearing the UWB positioning tag in real time.

(3) UWB positioning base station: The UWB positioning base station communicates with the positioning tag through the UWB signal, and then solves it through the back-end server-side positioning engine to realize the precise positioning function of the UWB positioning tag.

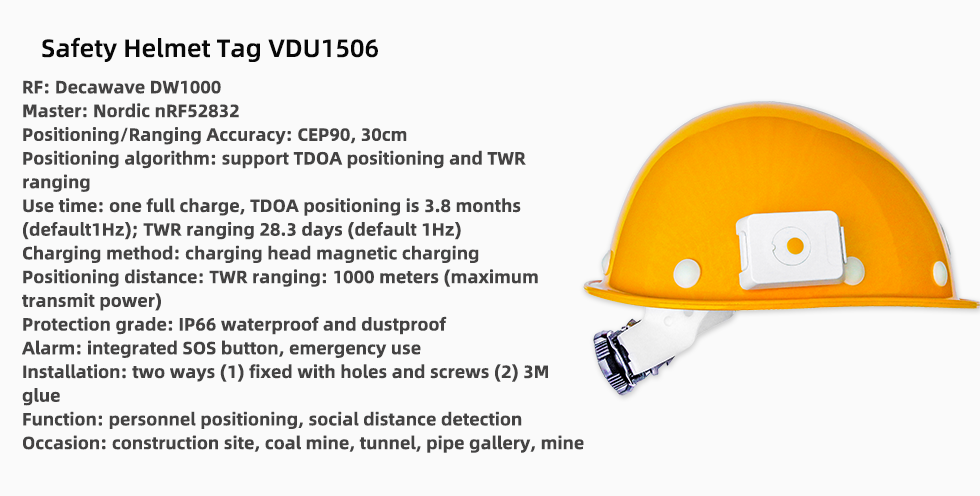

(4) UWB positioning tags: UWB positioning tags are provided on the personnel and equipment to be located, and the positioning tags emit UWB signals and communicate with the UWB positioning base station so that the tags themselves can be located. The UWB location tag can be a wristband type, a work card type, a module type fixed on a helmet, or a vehicle-mounted type fixed on equipment materials.

(1) Accurate real-time positioning of construction personnel and equipment;

(2) Statistics and management of construction personnel;

(3) Construction personnel or equipment movement track playback;

(4) Electronic fence;

(5) One-click call for help in dangerous SOS;

(6) Early warning/alarm: mainly includes real-time early warning, multiple types of early warning (SOS, low power, offline, stay overtime, fence), multiple early warning methods, hierarchical early warning management, early warning data recording and analysis, etc.

Copyrights© Shenzhen Skylab Co.,LTD All Rights Reserved.