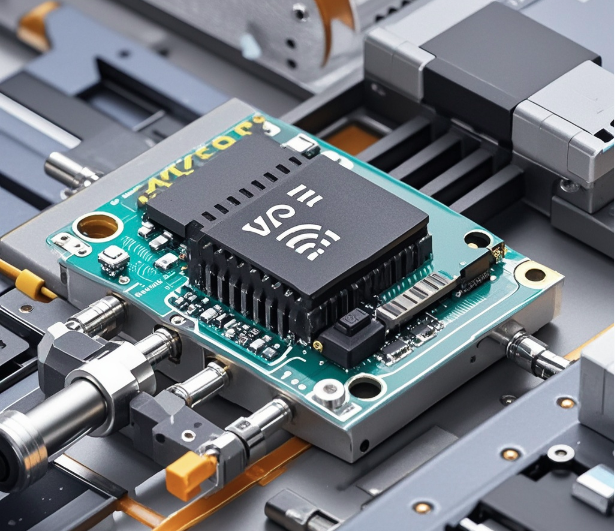

Industrial automation is the core of modern manufacturing, aimed at improving production efficiency, reducing costs, enhancing product quality, and ensuring the stability of the production process. With the rapid development of information technology, WiFi modules, as a key wireless communication technology, are playing an increasingly important role in the field of industrial automation. It provides a convenient and efficient solution for the interconnection and intercommunication between industrial equipment, promoting industrial automation towards intelligence and networking.

Challenges and Solutions Faced by WiFi Modules in Industrial Automation Applications

1. Signal interference and stability issues

There are various sources of electromagnetic interference in industrial environments, such as motors, frequency converters, welding machines, etc. These devices can generate strong electromagnetic interference during operation, which may affect the stability and transmission quality of WiFi signals. In addition, the building structure and metal equipment in the factory workshop can also cause obstruction and reflection of WiFi signals, leading to signal attenuation and the emergence of signal blind spots.

Solution:

Optimize WiFi network layout: When deploying WiFi networks in factory workshops, full consideration should be given to the environmental factors on site, and the location and number of WiFi access points should be reasonably selected. Try to avoid installing access points near electromagnetic interference sources, and increase the density of access points or use distributed antenna systems to enhance signal coverage and reduce signal blind spots.

Adopting anti-interference technology: Select WiFi modules and devices with anti-interference capabilities, such as products that support channel selection, frequency adaptation, signal enhancement, and other technologies. You can improve signal stability by setting the working channel of WiFi devices to avoid the channel where the interference source is located. In addition, MIMO (Multiple Input Multiple Output) technology can be used to simultaneously transmit and receive data through multiple antennas, improving signal transmission quality and anti-interference ability.

Signal shielding and isolation: For areas with particularly severe electromagnetic interference, signal shielding and isolation measures can be adopted. For example, installing metal shielding covers around devices such as motors and frequency converters to reduce the impact of electromagnetic radiation on WiFi signals. Meanwhile, shielded cables can also be used to connect WiFi devices, reducing the impact of external interference on signal transmission.

2. Network security issues

Industrial automation systems involve the production, operation, and core data of enterprises, and network security is crucial. WiFi network, as an open wireless network, is vulnerable to security threats such as hacker attacks, data theft, and malicious intrusion. If the security of WiFi networks is not guaranteed, it may lead to serious consequences such as production interruption, data leakage, and equipment damage for enterprises.

Solution:

Strengthen network access control: Adopt identity authentication and authorization mechanisms to authenticate devices and users connected to WiFi networks. Authentication can be performed using usernames and passwords, digital certificates, MAC address filtering, and other methods. Only devices and users that have been authenticated can access network resources. At the same time, fine-grained authorization management can be applied to the network resources accessed by users based on their roles and permissions, ensuring the secure use of network resources.

Encrypt communication data: Use encryption technology to encrypt and transmit data in WiFi networks to prevent data theft and tampering. At present, commonly used WiFi encryption protocols include WPA2 (Wi Fi Protected Access II) and WPA3. Enterprises should choose encryption protocols with higher security and regularly update keys to improve data security. In addition, VPN (Virtual Private Network) technology can be used to establish secure encrypted channels on public networks, enabling secure connections between remote devices and internal enterprise networks.

Regularly conduct network security checks and vulnerability repairs: Establish a sound network security management system, regularly conduct security checks and vulnerability scans on WiFi networks, and promptly discover and repair security vulnerabilities and hidden dangers in the network. Professional network security detection tools and software can be used to conduct comprehensive security checks on network devices, servers, applications, etc., ensuring the security of the network system. At the same time, it is necessary to strengthen the emergency response capability for network security incidents, develop comprehensive emergency plans, and take timely measures to deal with security incidents to reduce losses.

3. Real time and reliability requirements

The industrial automation production process requires very high real-time and reliability of data transmission, and any delay, loss, or error of data may lead to abnormalities or even accidents in the production process. However, WiFi networks may be subject to interference and congestion in some complex industrial environments, resulting in the inability to guarantee real-time and reliable data transmission.

Solution:

Optimize network configuration and parameter settings: Based on the real-time and reliability requirements of industrial automation systems, optimize and adjust the configuration and parameters of WiFi networks. For example, parameters such as transmission power, channel bandwidth, and data transmission rate of WiFi devices can be adjusted to improve the efficiency and stability of data transmission. At the same time, QoS (Quality of Service) technology can be used to prioritize and allocate bandwidth for different types of data traffic, ensuring real-time transmission of critical data.

Adopting redundancy design and backup mechanism: In order to improve the reliability of WiFi networks, redundancy design and backup mechanism can be adopted. For example, in critical production processes, multiple WiFi access points can be deployed. When one of the access points fails, the other access points can automatically take over the work to ensure the continuity of data transmission. At the same time, important data can be backed up regularly to prevent data loss. In addition, it is also possible to consider using dual link or multi link communication methods. When one link fails, it will automatically switch to other links for data transmission, improving the reliability of the system.

Combining with other communication technologies: In some industrial scenarios that require high real-time and reliability, WiFi technology can be considered to be combined with other communication technologies, such as industrial Ethernet, Bluetooth, etc. For example, in some industrial equipment that requires real-time control, industrial Ethernet can be used for real-time data transmission, while WiFi modules can be used for remote monitoring and management of the equipment. This can fully leverage the advantages of various communication technologies and improve the overall performance and reliability of industrial automation systems.

WiFi modules, as a convenient and efficient wireless communication technology, have broad application prospects in the field of industrial automation. It provides wireless solutions for the interconnection and intercommunication between industrial equipment, promoting the development of industrial automation towards intelligence and networking. Although there are still some challenges in the application process, such as signal interference, network security, real-time and reliability issues, these problems can be effectively overcome by adopting corresponding solutions, such as optimizing network layout, strengthening network security protection, adopting redundant design, and combining other communication technologies, fully leveraging the advantages of WiFi modules in industrial automation. With the continuous development and improvement of WiFi technology, as well as the growing demand for industrial automation, it is believed that WiFi modules will be more widely applied and promoted in the field of industrial automation, providing strong support for the transformation and upgrading of industrial manufacturing and high-quality development.

WiFi module suitable for industrial automation applications in Tiangong Measurement and Control

1. SKW1003:

Features: This is an 11ac dual band AP/Router WiFi module that complies with 802.11a/b/g/n/acWiFi solutions. It integrates a dual core MIPSCPU (650MHz) and a 5x10/100Mbps Ethernet switch, supporting USB 2.0 and UART interfaces. The module integrates 2.4GHz 2x2MIMO WLAN chip and 5GHz 1x1WLAN chip internally, with built-in PA and LNA, and has good signal transmission capability in different frequency bands.

Advantage: It has a high data transmission rate and can meet the demand for fast transmission of large amounts of data in industrial automation. Supports multiple working modes, such as AP mode, client mode, relay mode, and router mode, which can flexibly adapt to different network architecture requirements in industrial automation scenarios.

Application scenario: Suitable for industrial automation equipment that requires high-speed data transmission and flexible networking, such as remote monitoring and control of industrial robots, data collection and transmission of automated production lines, etc.

2. WG23759:

Features: It is an industrial serial port WiFi6+Bluetooth 2-in-1 module. Built in ESP32-C3 chip and RISC-V32 bit single core microprocessor, with a maximum clock frequency of 120MHz. WiFi supports IEEE802.11b/g/n/ax protocol, while Bluetooth supports Bluetooth 5.0 and Bluetooth mesh. Adopting SMD-22 patch stamp hole packaging, it is small in size, convenient for embedded soldering, and integrates a large number of peripheral interfaces.

Advantages: With powerful processing capabilities and abundant interface resources, it can meet the connection needs of industrial equipment for various external devices. Support remote OTA upgrade, facilitating functional updates and maintenance of modules in the future. The working temperature range is -40 ℃~85 ℃, and a high temperature resistant version of -40 ℃~105 ℃ can also be customized to adapt to harsh temperature conditions in industrial environments.

Application scenarios: It can be widely used in industrial automation scenarios such as self-service terminal devices, building automation, industrial control, remote control, etc., such as networked communication of intelligent warehousing equipment, smart meters and other devices in smart factories.

3. LCS62604:

Features: It is a low-cost serial WiFi module based on the domestic chip Quanshengwei TR6260 solution, supporting 2.4GHz single frequency 802.11b/g/n. Powered by 3.3V, using PCB antenna or IPEX mount, with a size of 24.016.02.4 (mm), compact and easy to integrate.

Advantage: The low power consumption feature is suitable for industrial automation application scenarios with strict power consumption requirements, which can reduce the overall energy consumption of the equipment. Supporting serial port transparent transmission, it can meet the data transmission requirements of the Internet of Things, and can be controlled through serial port AT commands, facilitating communication and control with industrial equipment. It can be integrated with cloud servers and applications, accelerating the intelligent design and development speed of products.

Application scenario: Suitable for networked communication of small smart devices in industrial automation fields such as smart homes, smart lighting, and smart buildings, such as smart sensors, smart switches, etc.

Prev:The advantages and specific applications of WiFi modules in industrial automation

Next:Mine tunnel personnel positioning scheme - UWB positioning technology

Copyrights© Shenzhen Skylab Co.,LTD All Rights Reserved.