Electric energy is the foundation of the development of modern society, and timely and effective line inspection is a necessary means to ensure the safety of power supply. In the original line inspection, there are many problems and problems. The transmission lines are long, the manual inspection is time-consuming and labor-intensive, the efficiency is low, there are visual blind spots, and the safety is difficult to guarantee.

In response to many of the above problems, SKYLAB and MMC developed a solution for automatic inspection of UAV transmission lines.

Through the preparation of the UAV's route, the automatic cruise automatically collects. The UAV uploads the image information, automatically analyzes the defects, and automatically forms a defect report. Provide integrated solutions for line inspection for power transmission departments.

1、Transmission lines digitized with drone lidar

2、Organize the digitized transmission line/tower information through the UAV data platform

3、Send the lines and content that need to be inspected to the UAV terminal platform through the UAV data platform

4、Utilize RTK precise positioning to operate UAV for automatic flight

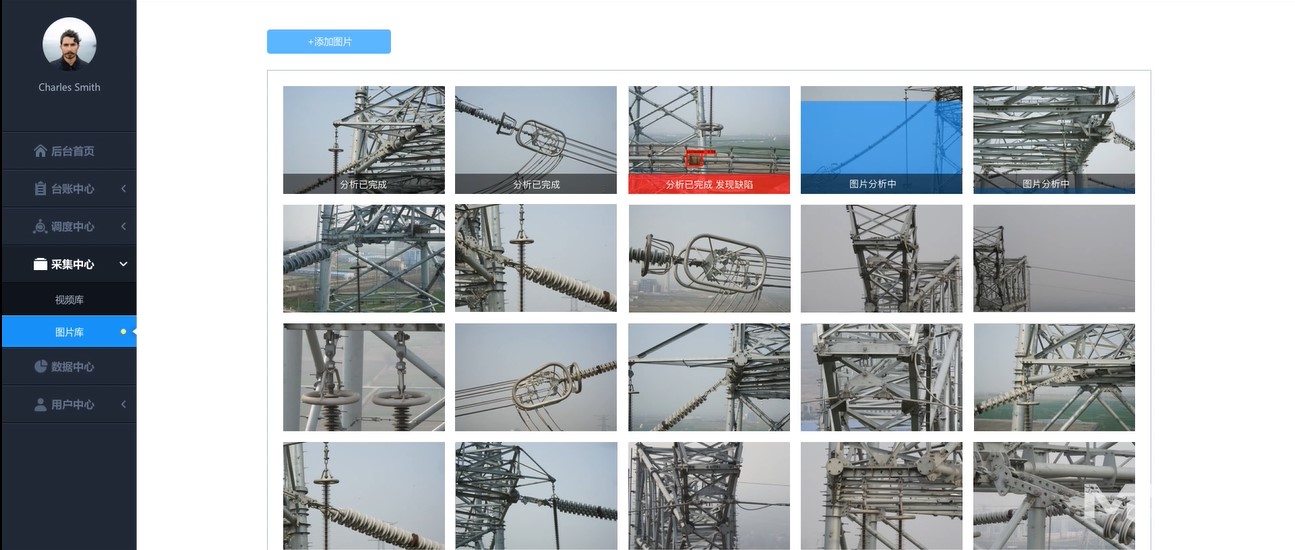

5、After the data is obtained, the platform is used for defect analysis.

Drones use laser point clouds to model transmission lines. Based on 3D laser and time image processing, it provides a 3D visualization operation mode. A three-dimensional corridor is formed, and the steel tower can be quickly identified on the basis of the three-dimensional corridor by combining the information of the existing single card of the transmission line. And form a lighthouse-based single-tower inspection route, the route information includes necessary hovering points, shooting angles, etc.

In the process of automatic cruise, the drone can automatically send back the pictures taken by the hovering point to the management platform. After the cruise, a system defect report is automatically formed, and the user can go to the scene according to the report to rectify and deal with the conveying equipment.

The inspection plan of the transmission line by unmanned aerial vehicle greatly improves the accuracy and operation efficiency of inspection. It significantly reduces the loss of manpower and material resources, improves the speed of analysis and maintenance, eliminates hidden dangers and faults in a timely manner, and effectively guarantees the safety of power transmission.

1、High efficiency, supports autonomous inspection, and performs tasks around the clock, which is 40 times more efficient than traditional manual inspection.

2、Low cost, low cost of construction, maintenance and use.

3、Easy to carry, simple to operate, vertical take-off and landing, low environmental requirements for take-off and landing. In the event of a sudden failure, it can respond quickly.

4、The full carbon fiber structure design realizes industrial three-proof, high temperature and high humidity resistance, and can still perform line inspection tasks in haze, rain and snow weather.

5、High safety, the working mode of man-machine separation avoids line patrol personnel from being in a high-risk working environment.

6、The body is small, and the automatic obstacle avoidance function can effectively prevent damage to the line.

Missing tower material, loose bolts, missing number plate, bird's nest, icing, collapsed tower, etc.

The protective cap of the tower base is buried, the fill is taken or sunk, the slope protection is damaged, etc.

The wire is deformed and broken, the wear between the spacer bar of the equalizing ring, the burnt by the fault current, the overheating of the crimping tube, the foreign matter, etc.

Broken strands, abrasion, lightning burns, foreign objects, etc.

Flashover traces, icing, current burns, fouling and self-explosion, fouling, exposed mandrel, damp heat, abnormal discharge, low value zero value, etc.

All kinds of wire clips are damaged, the pressure equalizing ring is damaged, the spacer bar is deformed and moved, and the displacement of the shock-proof hammer is lost, etc.

Discharge burns, exposed ground wire, loose bolts, etc.

Wires are rusted, worn, slack, missing fixtures, etc.

Line corridors have quarries, tall trees, housing construction, and other hazards.

Copyrights© Shenzhen Skylab Co.,LTD All Rights Reserved.